What is Temporary Scaffolding and Why is it Essential for Builders?

Temporary scaffolding is a crucial support system used in construction. It provides builders with secure platforms to safely access elevated work areas. This modular framework is made up of steel or aluminium tubes, boards, and connecting components that create stable working surfaces at different heights around buildings and structures.

You’ll find temporary scaffolding being used in every stage of building projects. Whether it’s during the initial construction phase or when adding the final touches, these structures enable tradespeople to work efficiently at height while always maintaining three points of contact. The system spreads out the weight evenly across multiple support points, making it a reliable base for heavy equipment and building materials.

Worker safety is extremely important when it comes to maintenance and repair tasks on existing structures. Scaffolding eliminates the dangers that come with using ladders and offers:

- Stable platforms for extended work periods

- Safe storage areas for tools and materials

- Protection barriers around work zones

- Secure access routes to hard-to-reach areas

The construction industry depends heavily on scaffolding for projects ranging from residential renovations to large commercial developments. It’s impossible to meet proper building standards without ensuring that workers have safe and stable access to their work areas. Scaffolding turns dangerous tasks involving heights into manageable ones, leading to fewer accidents and increased productivity across Australian construction sites.

This vital infrastructure supports not only workers but also the entire construction process as a whole.

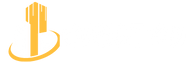

How Does Scaffold Mesh Enhance Safety on Construction Sites?

Scaffold mesh safety transforms construction sites into controlled environments where workers can operate with confidence. This specialised netting material creates a protective barrier around scaffolding structures, addressing multiple safety concerns that arise during building projects.

The primary function of scaffold mesh centres on debris containment. When you’re working on elevated platforms, tools, materials, and construction debris naturally fall or get displaced by wind. Scaffold mesh captures these falling objects before they reach ground level, preventing potential injuries to workers below and protecting pedestrians on busy streets.

Worker protection extends beyond debris containment. The mesh acts as a visual barrier that helps workers maintain their bearings at height, reducing the disorientation that can lead to falls. You’ll find this particularly valuable when working on multi-storey projects where depth perception becomes challenging.

Urban construction sites benefit significantly from scaffold mesh installation. The controlled environment it creates reduces accident risks by:

- Containing dust particles that can impair visibility and respiratory health. In fact, eliminating dust particles in the air with effective filtration is crucial for maintaining worker health.

- Blocking wind-borne debris from affecting adjacent properties

- Creating defined work zones that separate active construction areas from public spaces

- Reducing noise transmission to surrounding areas

Construction companies report measurable decreases in incident reports when scaffold mesh is properly deployed. The mesh doesn’t interfere with essential ventilation whilst maintaining the protective barrier that keeps both your workforce and the public safe from construction hazards. Additionally, in scenarios where wildfires pose a risk, scaffold mesh can provide an extra layer of safety by containing harmful debris and protecting workers during cleanup operations.

How Does Scaffold Mesh Protect Against Weather?

Weather-resistant scaffold mesh makes construction sites easier to work on by solving various environmental problems. It is made from high-quality polyethylene materials with added UV stabilizers, making it strong enough to withstand Australia’s harsh sun without getting damaged or brittle over time.

Benefits for Workers

The protective features of scaffold mesh go beyond just covering the area. Here are some ways it helps workers:

- Provides significant UV protection during outdoor tasks, reducing heat stress and sun exposure risks

- Creates effective wind shelter while still allowing air to flow through

- Keeps work areas cleaner and more comfortable by deflecting rain and dust

- Regulates temperature by reducing direct sunlight on the site

Addressing Wind Concerns

One of the challenges with solid barriers is that they can create pressure buildup during windy conditions. This is where the intelligent design of scaffold mesh comes in. Its partial air permeability helps reduce this pressure, keeping scaffolding structures stable even when there are strong gusts of wind.

This feature is especially important for high-rise projects where wind exposure becomes stronger as you go higher up.

Benefits for Specific Operations

You will find this weather protection particularly useful during concrete pouring operations. Here’s why:

- Consistent environmental conditions are crucial for proper curing of concrete

- By using scaffold mesh, you can reduce the chances of weather-related delays that lead to material waste

Overall, scaffold mesh offers multiple benefits for both workers and specific construction activities by providing effective weather protection.

Can Scaffold Mesh Improve Privacy and Aesthetics at Building Sites?

Construction site privacy becomes a significant concern when projects are located in busy urban areas or residential neighbourhoods. Scaffold mesh transforms unsightly scaffolding structures into visually appealing barriers that shield the construction process from public view. You can maintain professional site presentation whilst protecting your work area from unwanted attention and potential security risks.

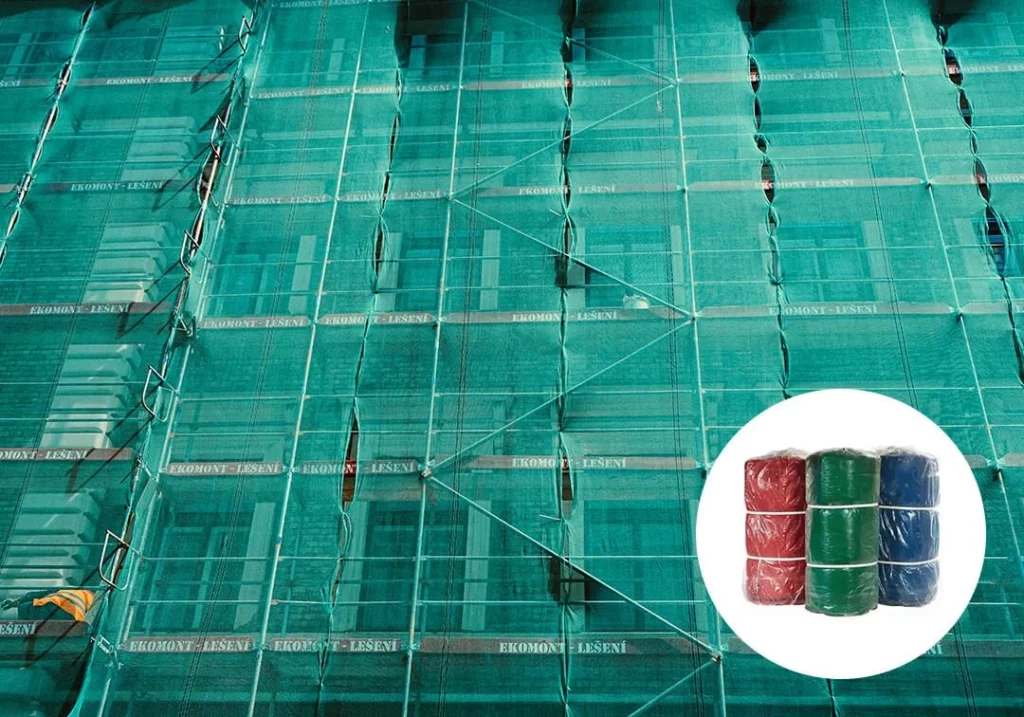

The aesthetic improvement scaffold mesh provides extends beyond simple concealment. Available in multiple colour options including:

- Black mesh – Professional appearance that blends with urban environments

- Green mesh – Ideal for projects near parks or residential areas

- Blue mesh – Corporate branding alignment for commercial projects

- Red mesh – High visibility for safety-critical applications

These colour variations allow you to match your company’s branding requirements or complement the surrounding environment. The mesh creates a cohesive visual barrier that presents your construction site as organised and professional.

Branding opportunities emerge through custom printing capabilities on scaffold mesh. You can display company logos, project information, or promotional messages directly on the mesh surface. This transforms your scaffolding into valuable advertising space, generating additional marketing value from necessary safety equipment.

The mesh maintains its protective functions whilst serving as a canvas for corporate messaging. Property developers frequently utilise this feature to showcase upcoming projects or highlight company credentials to passing pedestrians and potential clients.

Why is Scaffold Mesh Considered a Cost-Effective Solution for Builders?

Cost-effective safety solutions become crucial when managing construction budgets without compromising worker protection. Scaffold mesh offers exceptional value compared to solid barriers, which require more material and complex installation procedures. You’ll find that mesh installations cost significantly less than rigid boarding systems while providing equivalent safety standards.

Scaffold netting pricing remains competitive due to the material’s lightweight properties and simplified manufacturing process. A single mesh roll covers substantially more area than equivalent solid materials, reducing your material costs per square metre. The installation process requires fewer labour hours, as mesh attaches quickly to existing scaffolding frames using standard fixings.

Large roll dimensions, typically 2m x 50m, enable rapid deployment across extensive scaffolding structures. You can cover multiple scaffold bays in minutes rather than hours, reducing labour costs and project timelines. This efficiency translates directly into cost savings for your construction projects.

Budget-friendly construction materials like scaffold mesh maintain compliance with Australian safety regulations while delivering economic advantages. You avoid the expense of heavy-duty barriers without sacrificing protection for workers or the public. The mesh’s durability ensures multiple project reuse, spreading the initial investment across several jobs.

The material’s versatility eliminates the need for separate products for different applications. You can use the same mesh for debris containment, weather protection, and privacy screening, consolidating your material purchases and reducing inventory management costs.

How Does Scaffold Mesh Contribute to Worker Comfort and Site Efficiency?

Worker comfort scaffold mesh transforms the construction environment by creating optimal conditions for sustained productivity. The partial air permeability of quality scaffold mesh allows natural airflow to circulate freely around work areas, preventing the oppressive heat buildup that commonly occurs with solid barriers. You’ll notice workers can maintain their energy levels throughout longer shifts when proper ventilation reduces the greenhouse effect that traditional solid coverings create.

Wind reduction scaffolding capabilities become particularly valuable on Australian construction sites where coastal winds and seasonal weather patterns can disrupt operations. The engineered permeability of scaffold mesh reduces wind loading by approximately 30-40% compared to solid barriers, allowing air to pass through while maintaining structural stability. This wind resistance prevents dangerous scaffold movement that could compromise worker safety and project timelines, as detailed in this article on how weather conditions affect scaffolding projects.

The mesh design creates a controlled microclimate that balances protection with comfort. Workers experience:

- Reduced heat stress during summer months

- Better air circulation preventing stuffiness

- Stable working platforms even in moderate winds

- Consistent lighting conditions through filtered natural light

The benefits of using scaffold mesh extend beyond mere comfort. A study from the International Labour Organization highlights how improved working conditions directly translate to enhanced productivity metrics. Sites using properly installed scaffold mesh report fewer heat-related incidents, reduced worker fatigue, and improved task completion rates. The comfortable environment encourages workers to maintain focus on precision tasks rather than battling environmental discomfort, resulting in higher quality workmanship and fewer costly mistakes.

What Are Best Practices for Installing Scaffold Mesh on Temporary Scaffolding?

Proper scaffold mesh installation requires attention to detail and adherence to proven techniques that ensure long-lasting performance. Standard scaffold mesh rolls typically measure 2m x 50m, providing manageable dimensions that allow construction teams to handle installation efficiently without requiring heavy machinery or excessive manpower.

Securing scaffold netting begins with selecting appropriate attachment points along the scaffolding frame. You should space fixings at regular intervals of approximately 500mm to prevent sagging and maintain tension across the mesh surface. Cable ties, bungee cords, or purpose-built mesh clips work effectively for most installations, though you must ensure these fasteners can withstand wind loads and daily site activities.

The attachment technique directly impacts durability. You need to create slight tension in the mesh without over-stretching the material, which could lead to premature failure. Start from one corner and work systematically across the structure, checking alignment and tension at each fixing point. Pay particular attention to corners and edges where stress concentrations typically occur.

Temporary Scaffolding with Scaffold Mesh: Benefits for Builders become fully realised only when installation follows these guidelines:

- Check mesh orientation – ensure the correct side faces outward for UV protection

- Overlap joints by at least 150mm where multiple sheets meet

- Inspect regularly for loose fixings or damage that could compromise performance

- Allow for thermal expansion in hot climates by avoiding excessive initial tension

Quality installation protects your investment in both scaffolding infrastructure and mesh materials while maintaining site safety standards throughout the project duration.

How Does Scaffold Mesh Integrate with Other Construction Materials Like Reo Bars and Formwork Plywood?

Integration with reo bars becomes critical when you’re working on reinforced concrete structures. Scaffold mesh creates a protective barrier around scaffolding platforms where workers handle and position reo bars for concrete reinforcement. The mesh prevents dropped tools or materials from interfering with precisely placed reinforcement steel, maintaining the structural integrity of your concrete work.

Formwork plywood protection scaffold mesh provides extends beyond basic safety measures. When you’re setting up formwork systems using F14 or F17 plywood grades, scaffold mesh shields these expensive materials from weather damage and construction debris. The mesh creates a controlled environment around your formwork installation, reducing the risk of contamination that could compromise concrete finishes.

The protective environment scaffold mesh establishes proves essential for maintaining material quality. You’ll find that dust, debris, and moisture – common threats to both reo bars and formwork plywood – are significantly reduced within mesh-enclosed work areas. This protection becomes particularly valuable when you’re working with High-Density Overlay (HDO) plywood, where surface quality directly impacts concrete finish standards.

Temporary Scaffolding with Scaffold Mesh: Benefits for Builders extend to cost savings through material preservation. The mesh barrier helps prevent rust formation on reo bars in coastal environments whilst keeping formwork plywood surfaces clean and ready for reuse. This integrated approach maximises your investment in quality construction materials whilst maintaining site safety standards.

Related : Where to Buy Quality Scaffolding Mesh for Australian Projects